Wood Species and Finishes

Country View Woodworking is pleased to offer the following wood and finish options. Please check with your local retailer to to see actual samples prior to ordering, as monitor variations may not reflect actual colors.

Also note that since wood is a natural product, variations in color and finish may appear. See more at the right about those variations.

Notes on Wood Finish Variations

The appearance of a wood finish can vary significantly from one board to another, even if they are from the same type of wood and treated with the same finish. This is due to several factors that influence how the finish interacts with the wood. Some factors include:

Wood grain variation

Wood grain is a primary factor in how the finish appears. The pattern of the grain (straight, curly, wavy, or knotty) affects how the finish is absorbed. Open or porous grain (like oak) tends to absorb more finish and may appear darker or more textured than fine-grain woods (like maple or cherry). We select for the best grain match but please remember that Wood grain and color can even vary across individual boards. the variation in boards add character and interest to your furniture.

Porosity Differences

Some boards may have more open or coarse pores that soak up more finish, creating a more pronounced contrast in color or texture.

Knotty, Burl and Mineral Areas

Wood with knots, burls, worm holes or unique natural variations may absorb finish differently, often creating darker or more irregular patches. These areas can stand out when a finish is applied, making the board look inconsistent compared to a clean section of wood.

End Grain

All of our pieces are solid wood. this means that the end grain will show. this surface is softer and soaks up more stain therefore giving it a darker appearance.

Image above shows normal variations in wood grain color in maple using various finishes

Brown Maple $$

Maple wood is renowned for its exceptional beauty and versatility, making it a highly sought-after material in various woodworking projects.

Color and Grain: Maple wood typically exhibits a pale, creamy-white to light reddish-brown color, with occasional streaks of darker hues. Its grain is generally straight, although it can occasionally display subtle waves or curls, adding depth and visual interest to the wood.

Hardness and Durability: Maple wood is classified as a hardwood, renowned for its excellent strength and durability. It is notably resistant to wear, denting, and scratching, making it an ideal choice for furniture and flooring that experience heavy use.

Density and Weight: Maple wood has a medium to high density, giving it a substantial feel without being overly heavy. This characteristic makes it suitable for a wide range of applications, from intricate carvings to sturdy structural components.

Workability: One of maple wood's most prized attributes is its excellent workability. It machines, sands, and finishes exceptionally well, allowing craftsmen to achieve smooth surfaces and intricate details with ease. It also accepts stains and finishes uniformly, enabling a wide range of customization options.

Stability: Maple wood exhibits good dimensional stability, meaning it tends to resist warping, shrinking, and swelling due to changes in humidity and temperature. This stability makes it a reliable choice for furniture and cabinetry that require precision and longevity.

Versatility: Maple wood's versatility knows few bounds. It is commonly used in a myriad of applications, including furniture construction, cabinetry, flooring, musical instruments (such as guitars and violins), kitchen utensils, cutting boards, and even decorative veneers.

Distinctive Appearance: While maple's natural beauty is often appreciated in its unstained state, it also readily accepts a variety of finishes, allowing craftsmen to enhance or alter its appearance according to their preferences. From clear coats that highlight its grain patterns to darker stains that add richness, maple can be customized to suit any aesthetic.

Historical Significance: Maple wood holds a significant place in North American history and culture, particularly in regions where various species of maple trees are abundant. It has been used for centuries by indigenous peoples for tools, weapons, and housing, and it continues to be revered for its beauty and utility in modern times.

In summary, maple wood is prized for its timeless beauty, exceptional durability, and versatility in a wide range of applications. Whether it's crafting heirloom-quality furniture or adding warmth to a home's interior, maple wood's unique characteristics make it a perennial favorite among woodworkers and homeowners alike.

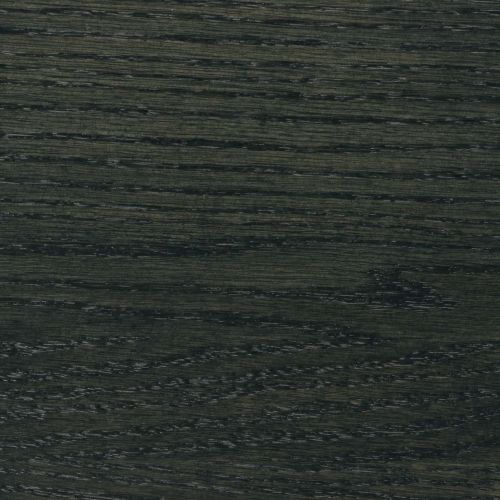

Red Oak $

Red Oak, renowned for its timeless beauty and sturdy nature, stands as a stalwart symbol of strength and elegance in the world of woodworking. Its scientific name, Quercus rubra, hints at its vibrant hue and robust presence. As one of the most prevalent hardwood species in North America, Red Oak boasts an impressive array of characteristics and features that make it a preferred choice for craftsmen and artisans alike.

Appearance: Red Oak's defining characteristic is its rich, reddish-brown hue, which radiates warmth and sophistication. Its grain pattern is bold and pronounced, featuring prominent rays and open pores that lend depth and character to each piece. With its distinct coloration and grain structure, Red Oak showcases a captivating blend of rustic charm and refined allure.

Durability and Strength: Renowned for its exceptional durability and strength, Red Oak ranks among the top choices for furniture, flooring, and cabinetry. Its dense composition and tight grain contribute to its remarkable resilience, making it resistant to wear, decay, and damage from insects and fungi. Whether used in high-traffic areas or exposed to the elements, Red Oak maintains its integrity and beauty over time, standing as a testament to its enduring quality.

Workability: Red Oak's workability is a boon to craftsmen, offering ease of machining, shaping, and finishing. While its density provides stability and support, it remains relatively straightforward to cut, plane, and sand, allowing for precise detailing and intricate designs. With proper tools and techniques, artisans can unleash their creativity, sculpting Red Oak into exquisite masterpieces that reflect both artistry and functionality.

Versatility: Versatility is a hallmark of Red Oak, as it lends itself to a myriad of applications across diverse industries. From fine furniture and architectural millwork to paneling and musical instruments, Red Oak's adaptability knows no bounds. Its ability to take on various stains and finishes further expands its versatility, enabling craftsmen to achieve a wide spectrum of colors and effects to suit any aesthetic preference.

Sustainability: As a native species to North America, Red Oak embodies sustainability and environmental responsibility. With responsible forest management practices in place, Red Oak continues to thrive and replenish its population, ensuring a renewable source of this cherished hardwood for generations to come. Its abundance and regenerative nature make it a sustainable choice for eco-conscious consumers seeking both beauty and integrity in their wood products.

In essence, Red Oak stands as a timeless icon of craftsmanship, blending strength, beauty, and sustainability into a harmonious symphony of natural excellence. Whether adorning the floors of a grand estate or gracing the tabletop of a humble abode, Red Oak leaves an indelible impression, inviting admiration and appreciation for its enduring legacy.

Wormy Maple $

Wormy Maple wood, also known as ambrosia maple or wormy ambrosia maple, is a unique and visually striking type of maple wood that exhibits distinctive characteristics due to infestation by ambrosia beetles. Here's a detailed description of its features and characteristics:

Appearance: One of the most striking features of wormy maple is its visually captivating appearance. The wood typically displays a range of colors, including creamy whites, light browns, and sometimes even shades of gray. The presence of dark streaks and patches adds to its rustic

Ambrosia Beetle Marks: Wormy maple gets its name from the ambrosia beetles that burrow into the wood and leave behind intricate patterns of tunnels and holes. These beetle marks, often referred to as "wormholes," are a defining characteristic of wormy maple and contribute to its unique aesthetic appeal.

Streaks and Stains: Alongside the wormholes, wormy maple often features streaks and stains caused by the fungus carried by the ambrosia beetles. These streaks can vary in color and intensity, ranging from dark gray to black, and they create visually interesting patterns throughout the wood.

Texture: Wormy maple typically has a moderately fine texture with a straight grain pattern. However, the presence of wormholes and fungal streaks can create variations in texture, giving the wood a more dynamic and tactile feel.

Density and Hardness: As a species of maple, wormy maple is generally considered to be moderately dense and hard. It offers good durability and strength, making it suitable for a wide range of woodworking applications.

Workability: Despite its density, wormy maple is relatively easy to work with using both hand and machine tools. It responds well to cutting, shaping, and sanding, allowing woodworkers to achieve smooth finishes and intricate details.

Finishing: Wormy maple accepts stains and finishes well, allowing for a range of customization options. Depending on the desired outcome, it can be left natural to showcase its unique characteristics or stained to enhance its color and depth.

Usage: Wormy maple is commonly used in furniture making, cabinetry, flooring, and decorative woodworking projects. Its distinctive appearance adds character and warmth to any space, making it a popular choice among designers and artisans.

In summary, wormy maple wood is prized for its unique appearance, characterized by the intricate patterns left behind by ambrosia beetles. Its natural beauty, combined with its workability and versatility, makes it a sought-after material for various woodworking applications.

Elm $$$

Elm wood is renowned for its strength, durability, and attractive grain patterns, making it a popular choice for a variety of woodworking projects. Here's a detailed description of its characteristics and features:

Grain Pattern: Elm wood typically exhibits a straight, interlocking, or wavy grain pattern, which adds visual interest to finished products. The grain can vary from fine to coarse, offering versatility in appearance.

Color: Freshly cut Elm wood often has a pale, creamy color with subtle reddish-brown undertones. However, as it ages and is exposed to light, it tends to darken, developing rich honey or golden hues. This natural aging process contributes to its unique beauty.

Texture: Elm wood possesses a moderately coarse texture with a smooth surface when properly finished. Its texture adds character and depth to furniture, flooring, and other applications.

Density and Hardness: Elm wood is known for its exceptional density and hardness, providing excellent structural integrity and resistance to wear and tear. Its density contributes to its impressive strength, making it suitable for heavy-duty applications such as furniture construction and flooring.

Workability: Despite its hardness, Elm wood is relatively easy to work with using both hand and machine tools. It has good machining properties, allowing for precise shaping, cutting, and carving. Elm also responds well to sanding, staining, and finishing techniques, resulting in a smooth, polished surface.

Stability: Elm wood exhibits moderate dimensional stability, meaning it is less prone to warping, shrinking, or swelling compared to some other hardwoods. This stability makes it an excellent choice for furniture and flooring applications where consistent dimensions are essential.

Resistance to Decay and Insects: Elm wood possesses natural resistance to decay and insect infestation, thanks to its high content of natural oils and resins. This inherent resistance enhances its longevity and makes it suitable for both indoor and outdoor use.

Unique Patterns and Figures: Elm wood occasionally features unique patterns and figures, such as burls, knots, and swirls, which further enhance its aesthetic appeal. These natural imperfections add character and individuality to finished products, making each piece truly one-of-a-kind.

Overall, Elm wood's combination of strength, durability, workability, and aesthetic appeal makes it a highly desirable material for a wide range of woodworking projects, from furniture making to architectural applications. Its timeless beauty and enduring quality ensure that Elm remains a cherished choice among craftsmen and designers alike.

Hickory $

Hickory wood is renowned for its exceptional strength, durability, and distinctive appearance, making it a popular choice for a wide range of woodworking projects. Here's a detailed description of its characteristics and features:

Color and Grain: Hickory wood typically features a pale to medium brown color with subtle variations in tone. One of its most notable characteristics is its pronounced grain pattern, which ranges from straight to wavy, adding visual interest and texture to the wood.

Strength and Hardness: Hickory is renowned for its incredible strength and hardness, ranking among the hardest and most durable domestic hardwoods available. This resilience makes it highly resistant to wear, denting, and impact, making it ideal for high-traffic areas and heavy-duty applications.

Shock Resistance: Hickory's exceptional shock resistance makes it a preferred choice for tool handles, sports equipment, and flooring in environments where durability is paramount. It can withstand heavy impacts without splintering or breaking, providing long-lasting performance.

Flexibility: Despite its hardness, hickory exhibits a degree of flexibility, allowing it to bend without snapping under pressure. This quality makes it suitable for applications such as furniture construction, where a balance of strength and flexibility is desirable.

Texture and Appearance: The texture of hickory wood is generally coarse and uneven, adding to its rustic charm. Its prominent grain pattern and occasional knots contribute to its distinctive appearance, making each piece of hickory unique.

Workability: While hickory is dense and challenging to work with hand and power tools, it can be successfully machined, sanded, and finished with the right techniques. Pre-drilling is often recommended for nails and screws to prevent splitting, and carbide-tipped blades are advisable for cutting.

Finishing: Hickory responds well to a variety of finishes, including stains, oils, and varnishes. Its natural beauty can be enhanced with clear finishes that highlight its grain pattern, or stained to achieve a darker, richer color while still showcasing its distinctive features.

Usage: Hickory wood finds applications in a wide range of industries, including furniture making, cabinetry, flooring, tool handles, sporting goods, and architectural millwork. Its strength, durability, and aesthetic appeal make it a versatile choice for both functional and decorative purposes.

In summary, hickory wood is prized for its remarkable strength, durability, and distinctive appearance. Its rugged beauty, combined with its versatility and resilience, makes it a preferred material for various woodworking projects where quality and longevity are paramount.

Premium Cherry $$$

Premium Cherry wood, sourced from the heartwood of cherry trees, boasts a unique set of characteristics and features that distinguish it as a prized material in woodworking. Here's an in-depth description of its qualities:

Rich Color: Premium cherry wood is renowned for its rich, warm tones ranging from reddish-brown to deep burgundy. Its color deepens and mellows over time with exposure to light, enhancing its beauty and adding a touch of elegance to finished pieces. The natural color variations within the wood contribute to its unique character and visual appeal.

Distinctive Grain Pattern: The grain pattern of premium cherry wood is typically fine, straight, and uniform, though it may occasionally exhibit subtle waves or irregularities. The wood may also feature occasional small knots and mineral streaks, adding to its rustic charm and aesthetic interest. The tight grain pattern enhances the wood's overall appearance and provides a smooth, consistent surface for finishing.

Texture: Premium cherry wood has a smooth and satiny texture that feels luxurious to the touch. Its fine texture allows for crisp detailing and intricate woodworking techniques, making it a favorite among craftsmen and artisans for creating heirloom-quality furniture and decorative pieces.

Workability

Workability: One of the hallmarks of premium cherry wood is its exceptional workability. It cuts, sands, and shapes easily with both hand and power tools, allowing for precise craftsmanship and intricate designs. The wood also holds screws and nails securely, making it suitable for various joinery methods and construction techniques.

Stability: Premium cherry wood is prized for its stability and dimensional reliability. When properly dried and seasoned, it exhibits minimal movement or distortion over time, ensuring long-lasting durability and structural integrity in finished pieces. Its stability makes it an ideal choice for furniture and cabinetry that require precision and longevity.

Finishing: Premium cherry wood responds beautifully to a variety of finishes, including stains, oils, and clear coats. Its rich coloration and smooth texture provide an excellent canvas for staining, allowing for customization to match different design preferences and decor styles. Additionally, a clear finish enhances the wood's natural beauty, bringing out its deep, lustrous tones and highlighting its exquisite grain pattern.

Usage: Premium cherry wood is prized for its versatility and timeless beauty, making it suitable for a wide range of applications in woodworking. It is commonly used in crafting fine furniture, cabinetry, flooring, interior trim, and architectural millwork, where its luxurious appearance and exceptional quality can elevate the overall aesthetic of any space.

In summary, premium cherry wood is celebrated for its rich color, distinctive grain pattern, and exceptional workability, making it a preferred choice among discerning woodworkers and designers. Its timeless beauty, combined with its durability and versatility, ensures that it remains a cherished material for creating exquisite, heirloom-quality pieces that stand the test of time.

Sap Cherry $

Sap Cherry wood, derived from the sapwood of cherry trees, possesses a distinct set of characteristics and features that make it a prized material in woodworking. Here's a comprehensive description of its qualities:

Color: Sap cherry wood typically exhibits a light, pale hue ranging from creamy white to a light pinkish-brown. Its coloration contrasts with the deeper reddish-brown tones found in the heartwood of cherry trees, creating a pleasing visual contrast in finished pieces.

Grain Pattern: The grain pattern of sap cherry wood is generally fine and straight, though it may occasionally display subtle waves or irregularities. This fine grain contributes to its smooth and uniform appearance, enhancing its aesthetic appeal in furniture and cabinetry.

Texture: Sap cherry wood has a smooth and even texture, with a natural luster that lends itself well to finishing. Its fine texture allows for crisp detailing and intricate woodworking techniques, making it a favorite among craftsmen and artisans.

Workability: One of the notable characteristics of sap cherry wood is its excellent workability. It cuts, sands, and shapes easily with both hand and power tools, allowing for precise craftsmanship and intricate designs. It also holds screws and nails securely, making it suitable for various joinery methods.

Stability: While sap cherry wood is generally stable and resistant to warping or shrinking, it is important to properly dry and acclimate the wood before use to minimize the risk of movement over time. Once seasoned correctly, it maintains its shape and dimension well, ensuring long-term structural integrity in finished pieces.

Finishing: Sap cherry wood responds beautifully to a variety of finishes, including stains, oils, and clear coats. Its light color provides a versatile canvas for staining, allowing for customization to match different design preferences and decor styles. Additionally, a clear finish enhances its natural beauty, bringing out the wood's subtle grain patterns and color variations.

Usage: Due to its attractive appearance, workability, and versatility, sap cherry wood finds wide application in furniture making, cabinetry, interior trim, and architectural millwork. It is particularly popular for crafting elegant pieces such as tables, chairs, cabinets, and decorative moldings, where its light color and smooth texture can enhance the overall aesthetic.

In summary, sap cherry wood is prized for its light color, fine grain, and excellent workability, making it a sought-after material for high-quality woodworking projects. Its versatility, stability, and natural beauty ensure that it remains a favorite among woodworkers and designers seeking both aesthetic appeal and functional durability.

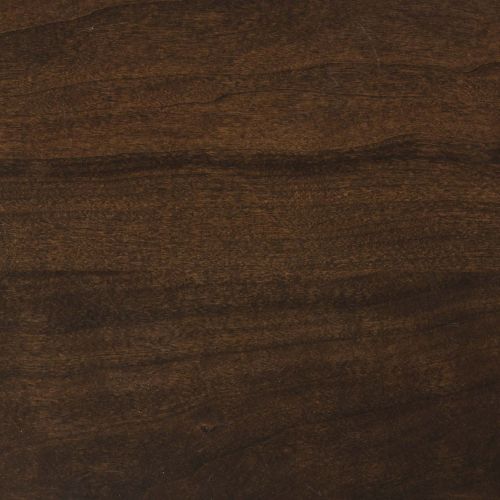

Sap Walnut $$$$

Sap Walnut wood, also known as "sapwood," is the outermost layer of the walnut tree trunk, contrasting with the darker heartwood. Here are the characteristics and features of Sap Walnut wood:

Color: Sap Walnut wood typically displays a lighter hue compared to the deeper tones of the heartwood. Its color can range from creamy white to pale yellow or light brown.

Grain Pattern: The grain pattern of Sap Walnut wood is often straight, though it can occasionally exhibit some waviness or irregularity. It may also feature subtle mineral streaks, adding visual interest.

Texture: This wood has a medium texture with a moderate natural luster. It has a smooth surface that takes well to polishing and finishing.

Durability: While not as durable as the darker heartwood, Sap Walnut wood still offers good overall durability and resistance to decay. However, it may be more susceptible to damage from insects and fungal growth compared to heartwood.

Workability: Sap Walnut wood is relatively easy to work with both hand and machine tools. It cuts cleanly and responds well to shaping, sanding, and finishing. However, care should be taken to avoid tear-out, especially when planing or routing.

Uses: Due to its lighter color and distinctive grain patterns, Sap Walnut wood is often prized for its aesthetic appeal in woodworking projects. It is commonly used in cabinetry, furniture making, interior trim, and decorative veneers. Additionally, it can be utilized in smaller specialty items such as turned bowls, boxes, and picture frames.

Staining and Finishing: Sap Walnut wood readily accepts stains and finishes, allowing for customization of its color and sheen to suit specific design preferences. Whether left natural or stained to match darker walnut tones, it retains its elegant appearance.

Availability: Sap Walnut wood is typically more readily available than heartwood since it constitutes the outermost layers of the tree trunk. Its availability makes it a popular choice for various woodworking projects where a lighter wood color is desired, offering a balance between aesthetics and affordability.

In summary, Sap Walnut wood showcases a lighter color and distinctive grain patterns, making it a sought-after choice for woodworking projects where its unique characteristics can be highlighted. Its moderate durability, workability, and versatility in finishing make it a valuable material for a wide range of applications in furniture making, cabinetry, and decorative woodworking.